Regional Platform of Surface Analysis

Scientifics and technicals managers :

Jean-François PAUL, Pardis SIMON, Nicolas NUNS and Martine TRENTESAUX.

|

For samples analysis, please fill in the Analysis Form (EN | FR) and send it to: Esta dirección de correo electrónico está siendo protegida contra los robots de spam. Necesita tener JavaScript habilitado para poder verlo. |

Organismes de financement

Organismes de tutelle

The platform is composed of three instruments (XPS, ToF-SIMS and LEIS) connected to each other via a radial distribution chamber under UHV.

X-RAY PHOTOELECTRON SPECTROSCOPY (XPS)

KRATOS AXIS UltraDLD (2009)

- 500 mm Rowland circle monochromator - Al Kα X-radiation (1486.7 eV)

- Dual anode Al Kα X-radiation (1486.7 eV) and Mg Kα X-radiation (1253.6eV)

- Hybrid magnetic and electrostatic optics with 165 mm hemisphere analyser

- Pass energy range – 5 eV to 160 eV

- Analysis area selection via aperture – 300 µm x 700 µm, 110, 55, 27 or 15 μm

- Snapshot spectra using delay-line detector

- 4-axis sample stage (x, y, z, θ) allowing angle-resolved studies for non-destructive depth profiling

- Temperature controlled sample stage with a range of -100 to 600 °C

- 5 keV Ar+ source for depth profiling and surface cleaning

- Charge neutralization – analysis of insulators to prevent sample charging

- Chemical state imaging at the micrometer scale using the spherical mirror analyser

In situ catalysis cell attached to the distribution chamber:

Samples can be treated under reactional stream (H2, CO, NO, O2… or liquid vapors) up to 900 °C, then transferred under vacuum towards XPS, ToF-SIMS or LEIS analysis chambers. Possibility to connect a mass spectrometer to analyze the gas output.

Sample submission

Samples that can be analyzed by XPS include: Catalyst powders, polymers, steels and metallic alloys, thin films…

Maximum sample sizes (l x w x h): 80 mm x 30 mm x 4 mm

Samples must be stable down to 2.10-10 mbar (no liquids except for ionic liquids; sublimation conditions for metal salts must be verified)

Samples can be sent to the address below:

Plateforme d’analyse de surface - UCCS UMR CNRS 8181

Université de Lille

Cité Scientifique, Bâtiment C3

59655 Villeneuve d’Ascq cedex

France

Recent application examples

Characterization of pseudocapacitive vanadium nitride thick films using coupled XPS and ToF-SIMS analysis (1)

Overview of the combined ToF-SIMS/XPS analyses at the surface, in the middle of the VN film, and at the VN/Si3N4 interface. Copyright A. Duchene / P. Simon / C. Lethien.

(1) K. Robert, D. Stiévenard, D. Deresmes, C. Douard, A. Iadecola, D. Troadec, P. Simon, N. Nuns, M. Marinova, M. Huvé, P. Roussel, T. Brousse, and C. Lethien, "Novel insights into the charge storage mechanism in pseudocapacitive vanadium nitride thick films," Energy Environ. Sci. (2020).

Determination of uranium oxidation state in a fluorinated ionic liquid [Bmim][PF6] (2)

XPS F 1s core level spectra and U 4f/N 1s core level spectra of the UF4 synthesised supernatant.

(2) F. Joly, P. Simon, X. Trivelli, M. Arab, B. Morel, P. L. Solari, J. Paul, P. Moisy, and C. Volkringer, "Direct conversion of uranium dioxide UO2 to uranium tetrafluoride UF4 using the fluorinated ionic liquid [Bmim][PF6]," Dalt. Trans. 49, 274–278 (2019).

TOF SIMS

Ion ToF, Tof SIMS5

Time-of-Flight Secondary Ion Mass Spectroscopy (ToF SIMS) is a very sensitive analytical technique, for many industrial and research applications. This technique uses a pulsed ion beam (here Bi+) to remove both atoms and molecules from the sample surface (< 4 monolayers). The secondary ions removed from the surface are then extracted and accelerated by an electrical field and their masses are then determinate by measuring their time of flight over the analyzer to reach the detector.

The time of flight analysis allowed a very high mass resolution, an unlimited mass range and a parallel detection of all ions.

ToF SIMS applications :

ToF SIMS offers infinity of possibilities to characterize materials, users imagination might be the only limit.

A wide range of industrial and research fields uses ToF SIMS : catalysis, corrosion, polymers, semiconductors, biomaterials, paper, metals, glass, coatings, pharmaceutical ….

The three main modes of analysis are :

- 1) Spectroscopy : High sensitivity in the ppm / ppb range, unlimited mass range, high mass resolution

- 2) Depth profile : Two ion beams operate. While the first beam (Cs or O2) is sputtering a crater, the second beam (Bi+) is progressively analyzing the crater bottom. The depth resolution is better than 1 nm and the sputter speed can be up to 10 µm/h

- 3) Imaging 2D or 3D : ToF SIMS machine offers the opportunity to perform chemical mapping of element or molecules with a high lateral resolution (< 100 nm). By combining depth profile with 2D imaging, it is possible to reconstruct 3D images

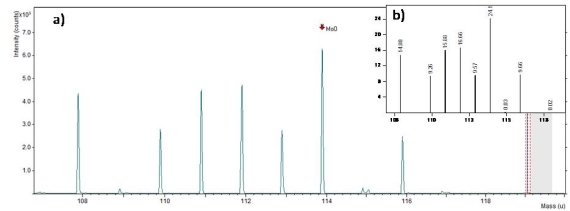

Figure 1 : a) ToF SIMS spectrum of Mo-based catalyst in the 107-120 uma range. The isotope cluster calculator (b) confirms that the seven main peaks correspond to Molybdenum oxide

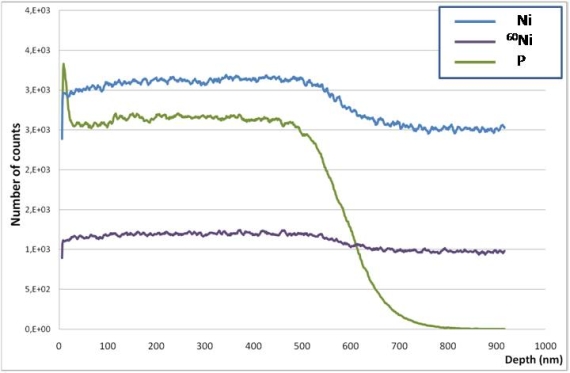

Figure 2 : ToF SIMS depth profile of a Ni/P coating on Ni

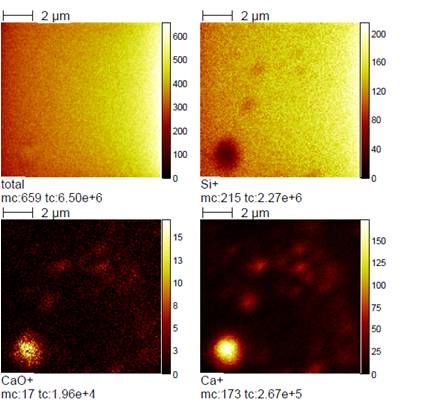

Figure 3 : ToF SIMS 2D imaging : Calcium particles are observed on silicon subtract

ION TOF / ToF SIMS V specifications :

Primary gun : Bi, Bi3

Mass Resolution : 104

Mass detection : parallel

Mass range : “unlimited”

Sensitivity : ppm / ppb range

Main application : Static SIMS, Dynamic SIMS

Lateral resolution : < 100nm

Raster precision : up to 1024 x 1024 pixel resolution

Field of view : from µm² to cm²

Sputtering gun : Cs and O2

Depth resolution : ≈ 1nm

Sputter speed : up to 10 µm/h

LEIS

Ion ToF, Qtac100

The Qtac is a high sensitivity low energy ion scattering (LEIS) instrument. It is extremely surface sensitive, providing elemental and structural characterisation of the top atomic layer. This new generation instrument has been developed to include small spot analysis, surface imaging, and both static and dynamic depth profiling. Its unique surface sensitivity makes the Qtac the perfect tool to study surface processes. The Qtac provides valuable information in many production and research areas on materials such as catalysts, semiconductors, metals, polymers, fuel cells, and biomaterials. Key features are :

- 3000 times higher sensitivity than conventional LEIS instruments

- Quantitative, elemental characterisation of the top atomic layer

- Spectroscopy, imaging and depth profiling capabilities

- Time-of-flight mass filtering for improved sensitivity

- Analysis of rough and non-conductive materials